3D Printing, digital fabrication, and applications of innovation in construction

We are a group of entrepreneurs and specialists with experience and a long-term interest in the fields of 3D printing, digital fabrication, design, and the use of natural materials in construction.

On a practical level, we are driven to create meaningful, scalable solutions with the power to positively transform lives — spaces that not only shelter, but teach, nourish, and evolve with their inhabitants.

........

AUTOM8

Architecture in Harmony with Nature

We envision architecture that resonates with the natural world — spaces that awaken the imagination and inspire dreaming.

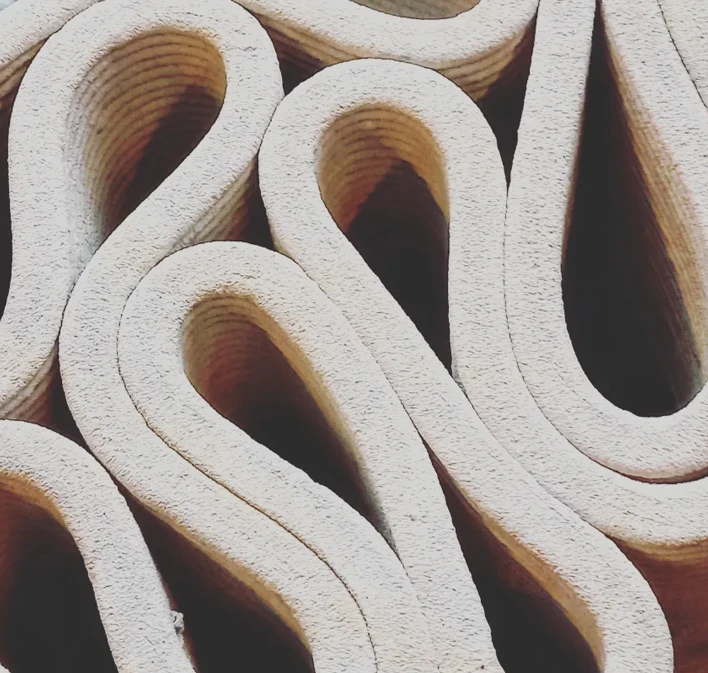

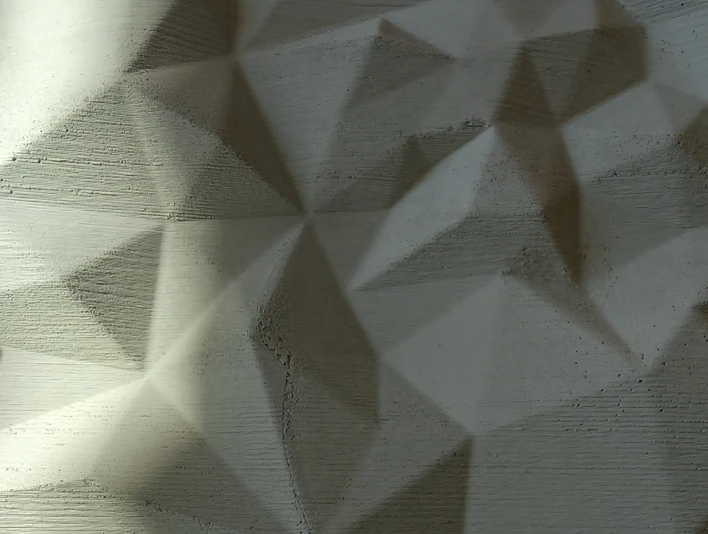

Rooted in principles of recyclability, biomimicry, and living systems, our work embraces nature-friendly materials and innovative technologies to create a new kind of comfort — one that feels both deeply human and otherworldly.

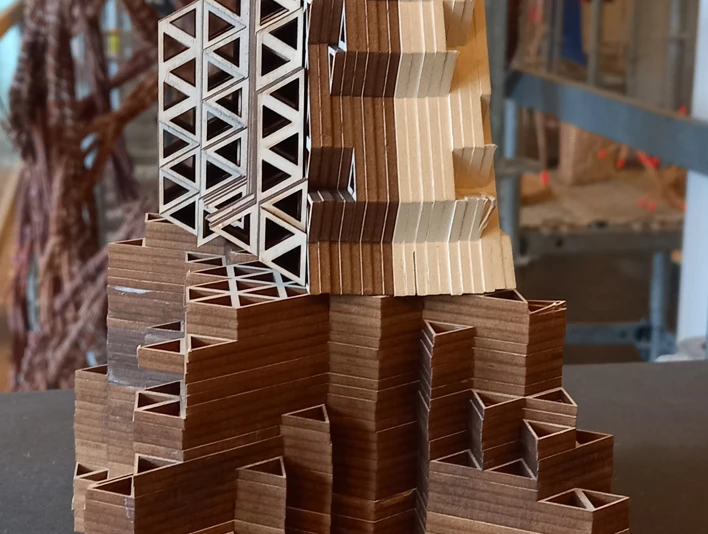

We are interested in the integration of digital technologies for sustainable construction, automation, prototyping, digital fabrication, and the exploration of new materials and technologies.

We explore the intersection of mechanics, sustainable materials, and future-forward design, crafting environments that support well-being, regeneration, and sensory connection.

ACTIVITIES

Research and scientific-experimental work in the field of 3D printing and digital fabrication.

..........................

..................

........................

....................

Development of innovative building components and technologies.

Development of start-up initiatives and participation in programs promoting Additive Manufacturing.

........

Opportunity to create joint business and commercial initiatives related to the industrialization of developed technologies.

.......................

..............

.......................

Conducting practical trainings and seminars with access to scientific laboratories, materials, and technological facilities.

.........................

........................

............................

............................

..........................

...........................

NEWS

..............

Observations from Formnext 2024: Between Industrial Ambition and Raw Reality

Frankfurt, Germany – Formnext 2024 once again gathered the world’s leading players in additive manufacturing. But behind the glitter of exhibition stands and bold promises lies a more grounded and realistic picture of where 3D printing stands today.

### An Industry Racing Ahead – But Where To?

Everyone seems to be in a rush to make 3D printing the next industrial revolution. Some print service providers have transformed into materials suppliers; others have pivoted from metallurgy to producing metal powders and printers. Yet no single technology has achieved real elegance. Nearly every printed part still needs post-processing—milling, sintering, or finishing—because most 3D-printed objects still resemble some kind of “splat,” whether on a micro scale or quite visibly. In short: there’s form, but not yet the finesse needed for a true end product.

### The Focus: Not Architecture, But... Space?

Most of the effort seems aimed at solving technical problems in industries that are "rich in money but poor in imagination"—healthcare, aerospace, and similarly high-stakes fields. Architectural printing? Almost no progress. Understandable, perhaps. Buildings aren’t priced by the gram, and materials are cheap—unless you’re building in China, where bricks are made from clay, and replacing rice fields with construction could mean food scarcity down the line.

### China Quietly Takes the Stage

Chinese companies are gradually but surely moving into central positions. At first glance it’s not obvious, but after a few conversations, it becomes clear: this isn’t accidental. Whether it’s subsidies, sheer scale, or "printing their own yuan," Chinese firms are settling in comfortably.

A simple example: 3D-printed sneaker designs sold for €170. One Chinese exhibitor told me, “We’ve sold… hang on… yeah, 125,000 pairs already.” And you know what? I believe him.

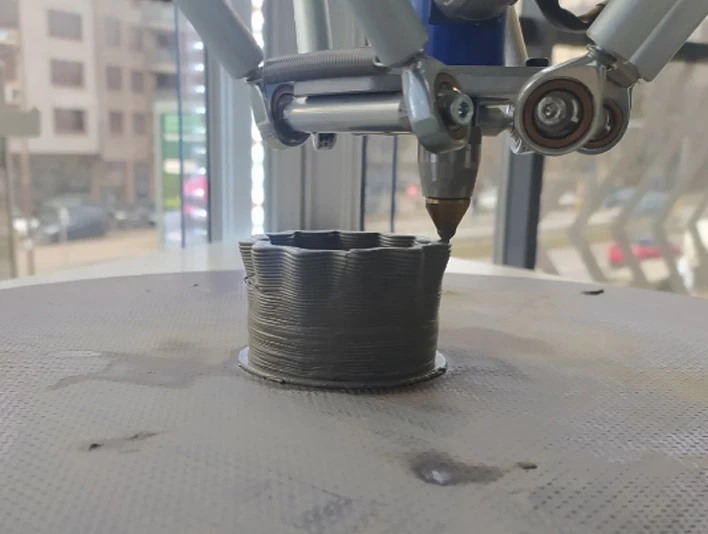

### So Many Technologies – But No Clear Focus

Technologies were everywhere: printing with polymers, ceramics, metals—even organic molecules (though the latter had only one academic showcase). Innovations in how the “materialization point” is positioned? Almost none. Most printers still work in a single plane, rotated or repositioned endlessly. CNC machines now come with extruders, and robots have rotating tables. In short: most of what we might need for our own project already exists. That’s good news—because once we solve our “headache,” scaling becomes a matter of picking a platform and setting a budget.

### But What If That’s Exactly What We Should Be Looking For?

Amidst the noise, one idea lit up the conversation: a variable-diameter, soft nozzle—ranging from 0 to 30 mm. Not rigid for wear-resistance, but flexible for adaptability and speed.

The idea didn’t come from a glossy brochure, but from a conversation with Bobi and Raiko), who shared some insights on the real-world problems of printing concrete. He promised to send me more documentation—but even without it, my brain is already in overdrive.

### What’s Next?

A variable-nozzle extruder capable of high-speed printing with concrete or clay could unlock massive potential—not just in construction. While we’re developing the hardware, the software for slicing and control will mature.

Our resources are limited, so focusing on the extruder is the smartest step forward. Exotic materials are a distraction—simplicity and controlled application are the way through.

Time to hit the drawing board!

This rapid-fire report was made possible by yet another delay from British Airways.

Observations from Formnext 2024 by Plamen Vasilev, 22.22.24.

OSAKA EXPO 2025 — Designing Future Society for Our Lives

A glimpse into the future… through a very old lens.

Osaka – one colossal project indeed. Upon descent into Kansai International Airport, you can’t help but notice the "evolution of the islands." At first glance, the strange fences in the riverbed or sea might be mistaken for fisheries. Then comes the slow realization — these are future islands in the making. Some feature farming activity, others are plastered with solar panels, and a few hint at industrial use. This is not 3D printing — it's the traditional, ancient Japanese art of land-making. Manual, muddy, and massive. Additive manufacturing at tectonic scale.

Fast forward to Expo 2025:

Set on one of these fully “grown” islands, the Expo grounds are dominated by a surreal sight: the Grand Roof, also called the Grand Ring — the largest wooden structure in the world. It loops overhead like an unused race track, dotted with footpaths, flowers, and manicured grass. Somehow both beautiful and horrifying.

Let’s talk numbers:

• ~27,000 cubic meters of timber used.

• That’s around 27,000 trees, assuming 40cm DBH (Diameter at Breast Height).

• These trees were at least 16 years old, each storing about 22 kg of CO₂ annually.

• All together, that’s at least 594 tons of carbon sequestration capacity erased anualy, not counting the emissions from drying, processing, and transporting it.

Yes, it’s impressive. But also, deeply un-Japanese in spirit. This is not a Kengo Kuma masterpiece — this is a lunch-break project by a bored, possibly obese Western architecture student, who Googled “sustainable” and stopped at “wood.” There’s no lightness, no play, no cultural nuance. Just 12 meters of hollow height — a timber brute with no real function. If architecture is meant to reflect maturity, then this monument raises a serious question:

Do we build things because we can… or because we should?

Designing Future Society for Our Lives

The slogan is bold, but reality is more tame. Yes, crowds are massive — some pavilions see over 40,000 visitors daily. Yes, there’s technology. Yes, the visuals are stunning. But beyond the queues and digital glitz lies very little you haven’t already seen on YouTube in 2018.

Visitors are shuffled in lines, like well-fed sheep, and served neatly portioned exhibits — an easily digestible speculative future made safe for all ages. You’ll find plenty of neon, screens, and “interactive” predictions about tomorrow’s life that somehow manage to feel like yesterday’s tech fair.

I hoped for something radical: architecture for post-humanity, immersive AI habitats, the kind of speculative design that redefines the human experience. Instead, I saw pretty facades and corporate reassurance.

A highlight?

Takenaka’s “Architecture That Becomes a Forest” – A poetic idea: 3D-printed rest pavilions made of plant-based resin, designed to biodegrade after the Expo and foster new forest growth. It’s thoughtful, biodegradable architecture — the opposite of the Grand Ring’s wooden monumentality. But even this feels more gesture than revolution.

And the main 3D-printed structure?

The modestly named “Printed Earthen Rest Facility” by WASP. Let’s call it what it is: Bog A 3D-printed one, yes — but following the most uninspired template from 1980s campground design. No domes, no arches, no curves or biomimicry. Just straight vertical walls, flat roof, conventional doors. Boring. Even the flowerpots, presumably to demonstrate flexibility, were printed with a laughable 15cm thick solid wall — because why not waste material if you’re already wasting opportunity?

If this were a design thesis, WASP and their collaborators would fail. Gloriously.

Observations by Plamen Vasilev, 28.06.2025